Automotive

plastics components

Vital protection

The use of soft PVC in protective layering for the chassis has doubled the average life of modern vehicles and drastically reduced the need for servicing and repairs. In order to make this protective layer, a paste known as plastisol is sprayed onto the metal underbody where it solidifies into a thin but extremely tough surface whilst the coating dries, helping to protect the chassis against grit (stone-chipping), dirt and water and thus minimising corrosion. The lightweight coating does not increase the petrol consumption of the car and requires no further servicing.

Soft PVC makes modern vehicles safer and more reliable. Electrical wires covered with flexible PVC sheathing are strengthened to resist shocks from the road whilst retaining the flexibility to withstand continuous mechanical stress, coping with the many sudden movements to which vehicles are subjected.

Flexible PVC cables are able to withstand heat when the engine is running and, at the same time, resist cold when, for example, the vehicle is left outdoors in winter.

Comfort and Safety

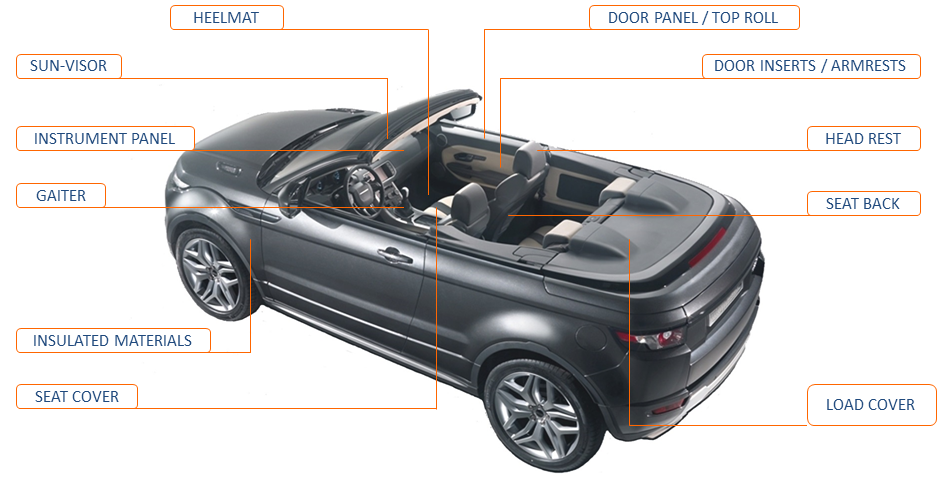

Plasticised PVC plays a critical role in reducing injuries and enhancing the appearance of cars. PVC covers for airbags and dashboards, for example, cushion impact in accidents. Very often in luxury cars, the instrument panel is covered with a flexible PVC skin to look and feel like leather while retaining all the safety advantages of the polymer and offering increased resistance to scratches. Cars are also quieter now thanks to the sound-dampening properties of soft PVC.

The versatility of the material enables manufacturers to achieve exact size, shape and texture specifications for door panels, arm rests, sun visors, rain strips and other small parts. Soft PVC is able to meet the challenges presented by difficult shapes much easier than alternatives, both in cost and quality.

Externally, soft PVC protects vulnerable areas such as doors from small impacts and scratches. It is found in body side protection strips, weather strips and window sealing profiles.

Cost-effective and environmentally sound

Flexible PVC offers unbeatable cost-effectiveness as it helps to make vehicles more affordable. For the environment, the lightness of soft PVC parts helps to reduce the weight of vehicles which, in turn, lowers wear and tear on roads at the same time that it decreases fuel consumption.